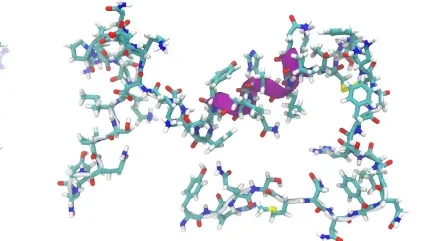

There’s a degree of precision required when combining ingredients that has always made chemistry something of a delicate practice. The creation of peptides, a process known as peptide synthesis, provides the perfect example. In order to synthesise a peptide – generally regarded as a chain of less than 50 amino acids – two or more amino acids must be bonded together in a process known as coupling. This might sound simple, but amino acids are highly reactive, and to achieve the required link without side reactions that can derail the process, chemical groups are added that bind to the amino acid reactive groups and protect the functional group from nonspecific reaction.

Although the first successful peptide synthesis was carried out more than a century ago, it wasn’t until the early 1960s that solid-phase peptide synthesis (SPPS), the most common technique for creating peptides today, was founded by American biochemist Bruce Merrifield. Iterative developments made since then have refined the process and turned it into the commercial enterprise we see today, and as a result patients around the world have benefited from peptide-based therapeutics.

One of the major impacts has been among patients with both type-1 and type-2 diabetes, where glucagon-like peptide 1 (GLP-1) medications can be a boon when traditional oral medications can’t get blood sugar levels under control. Currently, there are 80 approved peptide drugs on the market worldwide that exist to treat anything from cancer and autoimmune diseases to neurodegenerative and cardiovascular pathologies.

Of these peptide therapeutics, 38 were approved in the United States, Europe and Japan after the turn of the century, and there’s 170 currently being trialled for safety and effectiveness. It’s clear from these numbers that the peptide therapeutics market is growing rapidly – but manufacturers have a problem. “The process mass intensity of peptide manufacturing using Solid Phase Peptide Synthesis is a disaster,” Walter Cabri, full professor of organic chemistry in the Department of Chemistry ‘Giacomo Ciamician’ at the University of Bologna in Italy, says. He’s describing the total mass of materials used to produce a specified mass of peptide products – the measure used by chemists and engineers to evaluate levels of waste within their production processes.

But what does this look like in numbers? According to research highlighted in a recent paper co-authored by Cabri, peptides have a typical process mass intensity (PMI) of between 3,000kg and 15,000kg per 1kg of active pharmaceutical ingredient (API). “This PMI is one of the worst in the pharma industry,” says Cabri. Part of the reason for this, as Alessandra Tolomelli, associate professor in the Department of Chemistry ‘Giacomo Ciamician’ and co-author of the paper, explains, is that the peptide drugs sold today contain synthetic amino acids, and they can come at a high cost and require a large amount to achieve coupling due to being less efficient than their natural counterparts. “The problem of applying peptide synthesis for the production of these molecules is that you will have a high cost, because you’re using a very precious and expensive reagent that will be used in excess, and from the point of view of the atom economy, a lot of material goes to waste,” Tolomelli adds. “To refine the fragment you’re building from the excess of these reagents, you have to wash and wash with a large amount of solvent.”

There’s some context necessary to understand this point: The ‘solid’ part of SPPS refers to the resin upon which the reactions take place; the amino acids must be deprotected to prepare the chain for additional coupling steps, but to avoid any unwanted side reactions, any leftover reagents are dissolved, or ‘washed’, from the mixture using a solvent. The more reagent used to achieve a desired reaction and the longer it takes to complete the steps prior to the final ‘cleaving’ step, where the amino acid is removed from the resin, the more solvent that’s required to wash away the excess and prevent a compromising reaction. There’s also a final ‘purification’ stage that requires even more solvent to remove impurities, and the amount of these can vary depending on the efficiency of the coupling process.

Reliance on DMF

The reliance on solvent during the process, coupled with the fact that it’s estimated to account for between 80-90% of the PMI associated with peptide synthesis, means a huge amount of waste is generated, and that’s one reason for Cabri’s sentiments. The other reason is that dimethylformamide, or DMF as it is commonly referred to, is most often the solvent of choice, and it’s been under fire for some time now due to its less-than-ideal safety profile. DMF is the most common solvent seen in peptide synthesis due to its efficient reagent solubility and resin swelling properties, efficient removal of protective groups, and sufficient peptide coupling kinetics. “Technically, it’s perfect. But from an environmental and safety point of view, it’s a disaster,” says Cabri.

“The problem of applying peptide synthesis… is that you will have a high cost, because you’re using a very precious and expensive reagent that will be used in excess.”

Alessandra Tolomelli

These aren’t just risks subject to discussion and analysis among the academic community either; as of 12 December 2023, the industrial use of DMF will be heavily restricted in countries within the European Union due to an amendment to Annex XVII of the European Chemicals Agency’s regulatory framework REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). The reasons cited in a press release by the regulator when the restriction was announced in November 2021 was to protect workers from “liver and developmental effects and reproductive harm”.

The case for reducing solvent use in peptide manufacturing has been apparent for some time now, and there’s no shortage of research papers that propose green alternatives to DMF, or a mixture of solvents made to achieve a more efficient synthesis process. Cabri and Tolomelli themselves proposed such a mixture in a 2019 paper, but as Cabri notes, “people in production are very comfortable with the use of DMF”. There are two main reasons for this; the first is that the original SPPS method developed by Merrifield was designed around the solvent. “All the resin, the reagents, the protective groups, the activation systems are based on DMF,” says Cabri.

The second reason is more grounded in the risk tolerance of manufacturers, given the high cost of certain reagents. “When you have a reactor that’s doing solid phase synthesis, and you have in your reactor a molecule with a value of one or two million, you want to have an absolutely reliable technology,” Cabri adds. Given the level of automation applied to large-scale peptide synthesis, not having this reliability could be disastrous. “There is no correction you can use while you’re processing. That is why [manufacturers] are reluctant to move away from DMF,” explains Cabri.

This reluctance remains even after the plethora of papers proposing green alternatives to DMF, and it has provided an impetus for the team at Bologna to attack the problem from a different angle. “The resin is an area we are investigating by discussing with polymer chemists, in order to have resins that don’t require swelling and have good reactivity,” says Cabri. Tolomelli adds that the departmental group is working with the industry to achieve this goal. “If we can find a resin that is able to open up with almost every solvent, we can select a green solvent based on what we need for reactivity,” she explains.

The importance of this step isn’t just to do with the green credentials of the solvent either, because it’s one thing finding a new solvent or mixture that can lower the PMI of peptide production, but quite another to do so on a scale that’s cost effective – and that’s the bottom line for businesses. “The struggle is always the same. If you’re not able to reach a certain scale, the cost is not going down and you’re going to pay a price for that,” explains Cabri. He adds that the price for DMF is roughly £1 per kilogram, largely because it’s found in many industrial manufacturing processes and has strong economies of scale to support the demand and bring down the cost. “To reach that point is not so easy, but if you change the resin, you’re in a position where you can use standard green solvents,” Cabri adds. This means options like ethyl acetate, which is available at a reasonable cost but is not currently viable for use with the industry standard resins, could become viable.

Moving to liquid-phase synthesis

Finding a universally applicable resin would be a game changer for green peptide chemistry. But what Cabri and Tolomelli see as the gold standard is removing SPPS completely, in favour of solutionphase synthesis, also known as liquid-phase synthesis. “We are now deeply involved in solutionphase synthesis because the final target is to produce peptides using a flow approach,” says Cabri. “So, a very rapid approach in order to have, instead of three or four couplings a day, 20 couplings a day.”

Flow chemistry is a fairly recent ambition among experts in chemical synthesis, and essentially refers to a chemical reaction run in a continuously flowing stream, rather than in batch production. But one reason that SPPS has been preferred over liquidphase synthesis is the speed of production, and to make the latter viable for a flow chemistry approach to peptide manufacturing, each step in the process must happen fast. “We’ve already published a paper where we show that we are able to get the coupling in five minutes,” says Cabri. “If we’re able to get the deprotection in five minutes without generating much waste, we’re on the way there.”

Of course, the elephant in the room is peptide quality and the purity of the final product, which is uncertain given that the method isn’t mature enough to be tested at the industrial level. There’s also the fact that as of right now, a solution-phase approach is only viable for shorter amino acid chains, and the need for a step to couple longer fragments outside of the solution-phase approach has the potential to kill any efficiency gained using it to build them.

Optimising the process to overcome these barriers will be a herculean task, but with regulators cracking down on the use of DMF, Cabri and Tolomelli are optimistic that an increasing use of solution-phase synthesis will be part of an evolution in peptide synthesis, starting over the next five years with the adoption of resins that make green solvents viable, and ending with a fully contained flow chemistry method that leaves SPPS in the dust.