You can tell how important packaging is by the number of regulations that govern it. The huge list of rules dictating how to write accessible information, use Braille, and explain dosages, as well as the guidelines addressing naming rights, copyright and so on can be a headache for any compliance officer.

Another thing to consider is the possible effect of packaging on patients. This is usually minimised by blinding products; the current method of preparing supplies is to remove any commercial packaging prior to repacking.

Blinding or masking, according to CRO Almac Group, is “intended to limit the occurrence of conscious and unconscious bias in the conduct and interpretation of a clinical trial”.

It is used as a means to stop prior knowledge of treatments having an effect on how patients are recruited, allocated and cared for, as well as their attitudes towards the treatments they receive, the assessment of endpoints, the handling of withdraws and the exclusion of data from analysis.

Blinding makes patients “less likely to have biased psychological or physical responses to intervention; less likely to seek additional adjunct interventions; [and] less likely to leave [the] trial without providing outcome data, leading to lost follow-up”, according to CRO Almac.

Investigators are also less likely to transfer their inclinations or attitudes to trial participants administer co-interventions, adjust dose and withdraw participants, and less likely to encourage or discourage participation in a trial.

The burden

Easing these ‘burdens of blinding’ is an interesting challenge, but one that could bring amazing rewards. Providing subjects with unblinded medication and supplies may be a better way to approach the conundrum. Unblinded study medication and supplies can create greater flexibility, and cheaper study management, as well as better subject safety, adherence and retention.

The World Health Organization (WHO) disagrees. In its recent report, ‘Placebo and drug kits in clinical trial design’, it argued that, as many trials involved multiple clinical sites, blinding was absolutely essential. WHO is backed by Applied Clinical Trials Online (ACTO), which advises that successful blinding reduces bias in randomised trials.

However, a study’s integrity may be at risk when a blind is unintentionally broken. One idea is to regard this eventuality not as a problem, but instead as an opportunity for new ideas to flourish. One is arguably better off working from a position that acknowledges that total blinding is effectively impossible to guarantee.

Factors working against total blindness may include conditions in which packaging conditions cannot be met (sterile fill), or a sponsor lacking stability data for unpacking/repacking, or where the original packaging is essential to the operation of the product, or where equivalent components (inhaler parts, or syringes, for example) cannot feasibly be obtained elsewhere.

Almac Group adds that packmatching, whereby placebo treatments are designed to resemble certain commercial products, enable doubledummy designs to be used, while some dosage forms – such as inhalation devices – may be blinded using new technology. In short, the system is so heavily flawed that a rethink may be in everyone’s interests. Unblinded trials require collaboration in the early design stages. According to WHO, “Cooperation among regulators, ethics committees, and sponsors to reach consensus on key ethical and regulatory questions is essential, and has proved particularly valuable in situations of urgency and in low-resource environments.

“Efficient conduct of the trials without unnecessary regulatory barriers is equally important. Regulations on importation and dispensing of placebos for clinical trials, could delay access.”

Safety mechanisms

Well-designed clinical trials should also be complemented by postapproval safety assessment mechanisms, as many new medicinal products are introduced early, or into developing countries with limited pharmacovigilance capacities.

This applies particularly to unblinded trials.“New guidance has become available on safety surveillance,” says WHO, which proposes a structured process for evaluating whether or not significant knowledge gaps exist, or if passive safety surveillance is adequate.

According to ACTO, in terms of packaging, one must ensure that proper technology configuration for adaptive trials is set up and working efficiently. “Interactive response technology plays a large role in designing and controlling adaptive trials,” it says. This means that randomisation, the supply chain, and blinding strategy can remain robust and secure. “Preparing an adaptive design without adequate technology is not recommended, especially in larger trials.”

If a study sponsor does not have this technology in place, clinical supply professionals can help to select the appropriate software. Trial operators using unblinded procedures must therefore provide input into how drug packaging lists are configured; communicate batch releases that are recognised in the response technology; and establish a process for shipping materials based on orders sent by the technology to the depots, as well as providing input or authorisation to the materials being managed by the interactive response technology. Lastly, but not least, it must also ensure the naming and unitisation elements align with the physical nature of the materials.

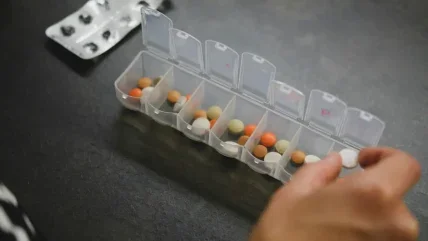

The goals of blinding in clinical trials packaging should always be to prevent or minimise the risk of patients’ ability to differentiate between products due to the shape, size, colour, texture, weight, taste, smell and rattling (for encapsulated products). It is essential, therefore, that new ways of achieving these goals continue to be developed.

How to meet the Brexit plastic challenge

The much-discussed ‘no deal’ between the UK Government and the European Union that might arise from a breakdown in Brexit negotiations could cost plastics manufacturers dearly. The British Plastics Federation (BPF) calculated in October that the cost of trade with the UK could rise by £880 million if no deal is struck.

According to Packaging News, the BPF believes the rise in cost of trade could occur if a trade deal is not established with the EU, and if WTO tariffs are applied to imports and exports. BPF research indicates that the cost of exports could increase by £340 million and the cost of imports by £540 million.

The chairman of the BPF’s Brexit committee, Mike Boswell, said, “It is clear that the EU is a vital market for the UK plastics industry and plastics are absolutely crucial to the success of the UK economy. The UK is a successful exporter of plastic materials, products and machinery but also remains highly reliant upon imports, making it absolutely essential that a favourable trade deal is struck with the EU.

“If no deal is reached, a significant increase in the cost of both exports and imports will undermine the competitiveness of the UK’s plastics sector at a crucial time for cementing existing trade links and exploring new opportunities.”

It gets more – and less complicated – when it comes to specific of operational guidelines for these providing packaging for clinical trials.

Nicola Maguire, a partner at law firm Cooley LLP, was quoted earlier this year by PMLive, saying that much EU clinical trial law framework had been built in to UK law so wouldn’t change with Brexit, but under the current regime, a sponsor of a clinical trial needs to have a legal representative established in the EU.

“Many US companies have chosen to establish such companies in the UK and these companies will continue to be suitable for that purpose for the time being,” she says. “Consideration will need to be given once there is some clarity as to how the UK’s status will be affected by a departure from the EU.

“There is precedent for a legal representative to be based in a country outside the EU, that is to say, a subsidiary in Switzerland is treated as a legal representative established in the EU for these purposes. Recently we have seen sponsors based outside the EU considering setting up subsidiaries in Ireland.”

With so much in the air, it remains essential that clinical trials operators keep fully abreast of the situation, and with legal frameworks being turned into such political scoring boards by both sides, it will mean making sure that packaging compliance becomes a bigger deal than it has ever been. Supply chains may also become rather more problematic.