Leak detectors are used for ‘on-site’ mobile leak detection, such as company premises, as well as for worldwide service jobs in a variety of different locations. Its leak detectors stand out above all due to their high performance combined with low weight.

The compact leak detectors are used first and foremost for stationary applications to detect leaks and test for leak tightness. They are also portable thanks to a special leak detector cart. Compact leak detectors are used in a wide range of industries, from applications in heavy industry right up to cleanroom applications. In the latter case, the dry versions of the leak detectors are being used.

Stationary high-performance leak detectors are used where extremely short cycle times and fast clean-up of helium background are required. Pfeiffer leak detectors of the ASM 192 and ASM 1002 series are used in applications ranging from large-scale testing of electronic components for leak tightness up to highly sensitive applications in vacuum and medical technology or research and development.

Multipurpose leak detectors

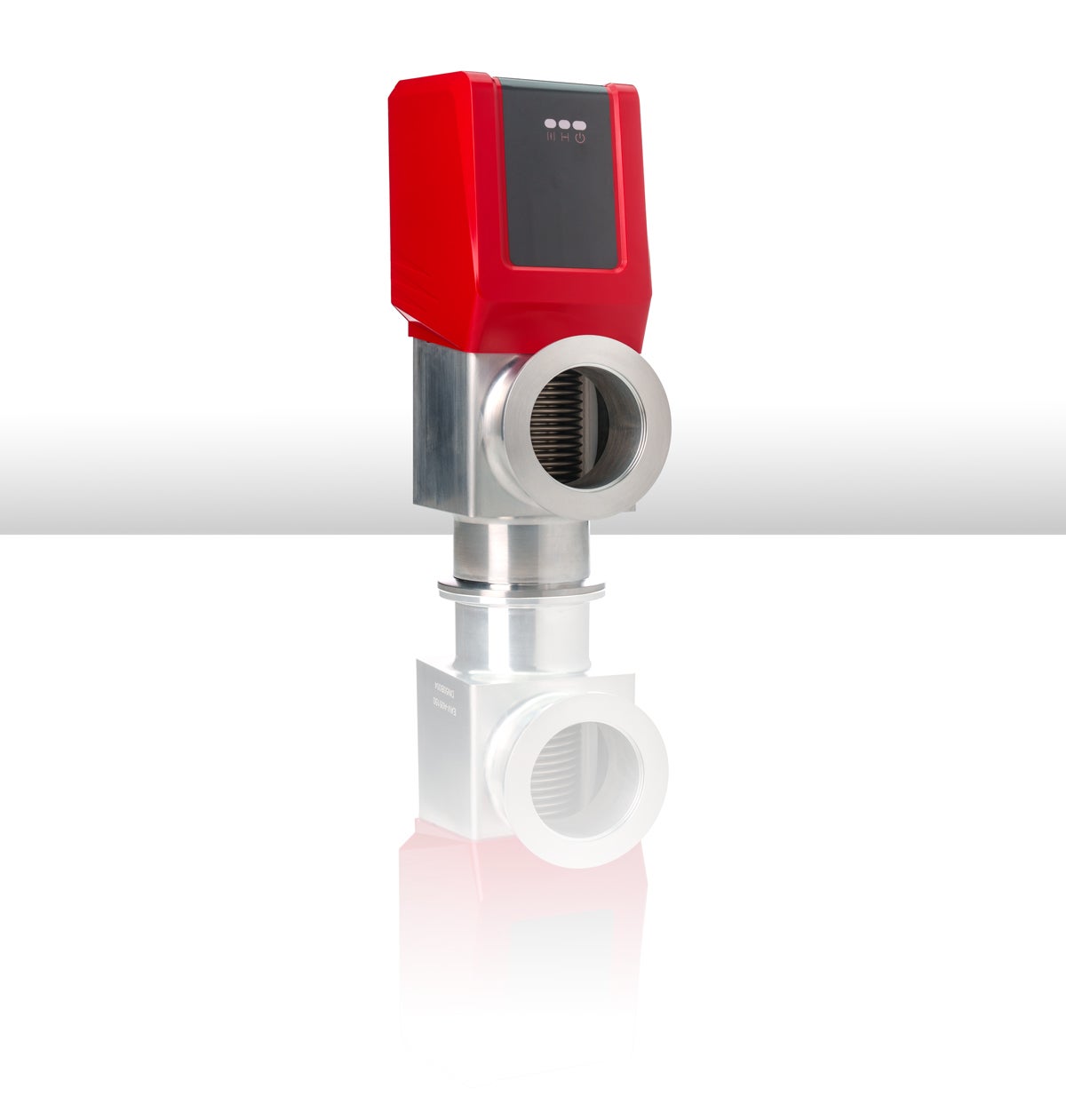

Multipurpose leak detectors combine performance and easy operation with the reliability that customers have come to expect. One such example is the ASM 340, a high-performance and durable leak detector for reliable quality assurance. The wide scope of application ranges from industrial and analytical applications to research and development, all the way to the coating market. The compact leak detector can be used in serial production and maintenance tasks.

Qualitative localisation of leaks and quantitative integral or local inspection are possible with the ASM 340 leak detector. It impresses with its efficient vacuum system, which guarantees that it is ready for immediate operation. Furthermore, it distinguishes itself with a fast response time, due to the high helium pumping speed. These features lead to a short cycle time and high throughput. The ASM 340 is the only leak detector in its class on the market that is capable of locating leaks starting at 100hPa.

A large selection of interfaces enables easy integration into production lines. The removable manual control element and the optional sniffer probe with LEDs make the work that much easier. Measured data can be recorded and evaluated using an SD card. The wireless remote control enables operation from a distance of up to 100m. Thanks to the robust design and the minimal maintenance required, service costs are also reduced.

Helium leak detectors

Helium leak detectors are the ideal solution for leak detection and leak-tightness testing under vacuum. The test gas helium is safe and a small, light molecule that is suitable for detecting micro leaks. The detection range of helium in vacuum tests lies between 10-2 and 10-13 Pa×m3/s. Helium leak detection is extremely accurate, quantitative and repeatable.

Manual sniffing or spraying is often the easiest way to detect a leak with helium. But it is also possible to use automatic leak detection solutions that are independent of the operator and provide a considerably higher detecting speed. The integral leak detection is designed to achieve predefined quality and component throughput levels.

The use of test gas leak detection methods has the bonus of delivering extra data compared with traditional leak detection methods such as bubble testing or pressure drop methods. These data can be used to improve production processes and successfully detect every leak.